Shoemaking town soars over 40 years of reform and opening-up

(chinadaily.com.cn )| Updated : 2018-12-20

Print PrintOver 40 years ago, Lancun town had made a name for itself and came to be known as No 1 Shoe Town, not just within Jimo district, or Qingdao city, or even Shandong province but across half the nation, northwards from the Yangtze River.

Forty years later, following China's reforming and opening-up, it has broadened its business from advanced manufacturing to logistics and e-commerce, and now reaches outside the country.

But to create such great change wasn't so easy. The glorious past of Lancun shoes was basically attributed to intensive labor. Every family in the town lived on shoe-making and weaving, and they managed to produce an incredible 100 million pairs a year.

However, that number could only meet one tenth of the huge domestic shoe demand. When labor costs rose and the workshop mode went out of fashion, the labor force started to drag the industry down and many small manufacturers had to produce under foreign brands.

Some entrepreneurs, notably Zhang Shi'an, the founder of Qingdao Xueda Group, are not meant to be trapped by competitors; their spirit of innovation is just too bright.

"The truth is that we were terribly cornered at that time by shrinking profits and complaining workers, and pollution problems, of course," Zhang said.

"The question of how to solve all these issues haunted us day and night until we determined to improve the scientific and technological content of our products."

And it did work.

Over 1000 enterprises in Lancun were reborn, and 46 are now above scale.

Xueda recently started massive private customized services, and some former shoe workshops are now supplying chair covers of the maximum flame retardant level for the domestic large aircraft C919 and the dining coaches of CRH bullet trains.

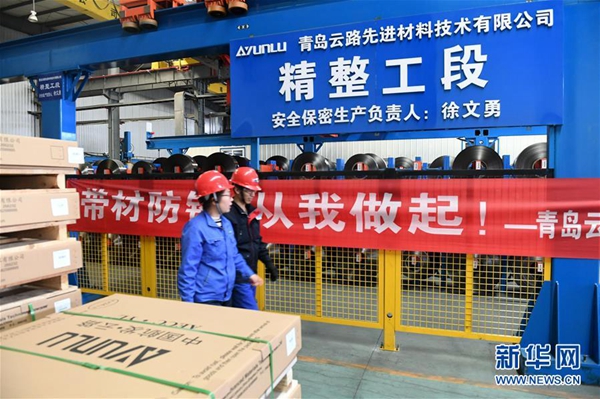

Another prize company in Lancun is Qingdao Yunlu Advanced Material Technology Co Ltd, established in 2015.

Through technology research and development, it broke Japan's monopoly on amorphous ribbon technology and became the only Chinese enterprise with a single line production capacity of 10,000 tons, reaching respective domestic and foreign market shares of 50 and 35 percent, which greatly reduced manufacturing costs.

Taking Yunlu Company as the main body, Lancun is constructing the AECOC's new material industrial park, a model of military and civilian integration. It covers an area of 137 mu and targets becoming the world's leading amorphous strip production base with an output value of over 10 billion yuan ($1.45 billion).

While hundreds of companies and groups focused on scientific and technological innovation, the government of Lancun was busy initiating scale effects by building various industrial parks or transportation networks one by one.

In July 2017, Qingdao Port Jimo Port Area; on Oct 29 this year, Lancun Rail Transit Industrial Park – both these projects made full use of Lancun’s central location: close to the two Qingdao airport hubs of Jiaodong and Liuting; covered by the Jiaoji, Qingrong and Lanyan railways and the planned Metro Line 16; and the meeting place of the Qingdao-Yinchuan, Qingdao-Xinhe and Qingdao-Weihai expressways.

The last pillar of "downtown Lancun" to arrive came in September 2018 when Lancun Town was officially approved as one of the first "E-commerce Towns in Shandong province".

At present, more than 50 enterprises have settled here and the annual turnover is expected to exceed 1 billion yuan.

The construction planning exhibition hall of Lancun town in Jimo district of Qingdao, Shandong province. [Photo/Xinhua]

An aerial photo of the e-commerce business area in Lancun town in Jimo district of Qingdao, Shandong province. [Photo/Xinhua]

The plant of Qingdao Yunlu Advanced Material Technology Co Ltd. [Photo/Xinhua]